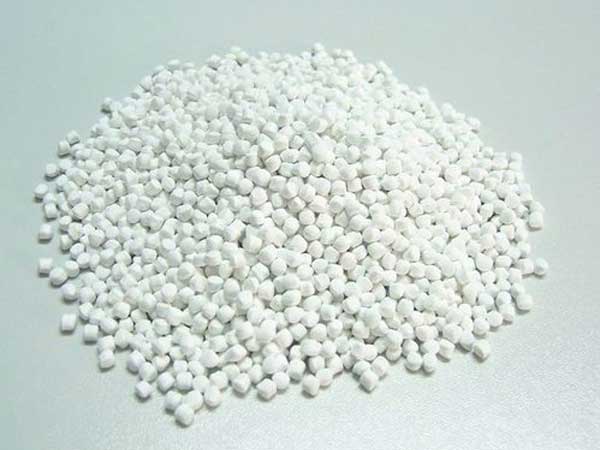

Plastic Granules

LLDPE

Linear low-density polyethylene (LLDPE) is used in films and packaging due to its flexibility and toughness. High-density polyethylene (HDPE) is typically translucent and less flexible than LDPE. Due to its higher crystallinity, it has better chemical resistance, stiffness, and strength than LDPE.

LDPE

Low density polyethylene (LDPE). This clear or translucent plastic exhibits flexibility, chemical resistance, and waterproofing capabilities. It is used in the manufacture of a wide range of products, including grocery bags, plastic wrap and film, flexible packaging material, and injection molded parts.

H.M. HDPE

HMHDPE (High Molecular High-density polyethylene) grade has higher molecular weight compared to HDPE and hence is extensively used for wear or abrasion resistant components.

P.P.

Recycled Polypropylene (PP) aka pp granules is used in manufacturing of wide range of products including packaging for consumer products, automobile plastic parts, textiles, etc.

VCI Master Batch

VCI is a class of chemical compounds that emit rust-inhibiting vapors into an enclosed air space. When metal is present, the VCI molecules form a nano-sized layer of protection on the surface of ferrous and non-ferrous metal that displaces moisture and prevents corrosion.

Anti Block Agents

Anti-block agents, also referred to as anti-slip agents, assist in minimizing surfaces from interacting with one another either through adhesion or other forces. These materials form barriers between surface layers and modify the frictional properties of the surface.